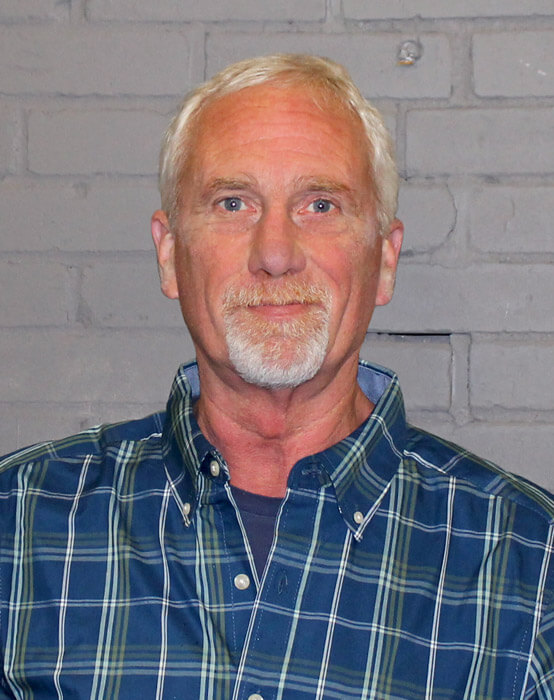

Founder & CEO

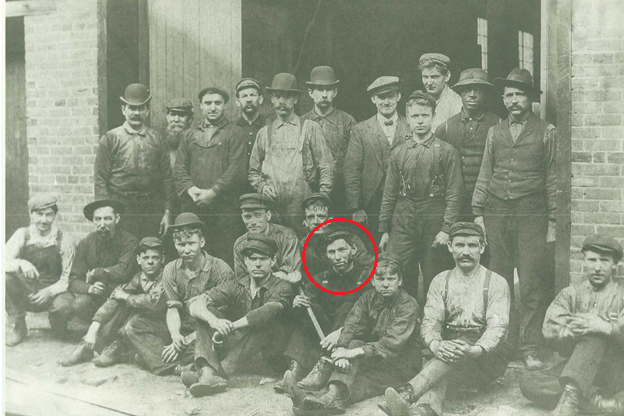

Joe founded JGM in 2001 after serving as a welder for a local steel fabricator in high school. Joe specializes in getting things done quickly, solving the thorniest challenges for clients and developing young talent. As the fifth generation Messner who started a construction and fabrication company, the entrepreneurial spirit has always been in Joe’s blood. Plus, he’s an avid supporter of various nonprofits and believes in giving back to the community that has given him so much. During his down time, Joe enjoys spending time with his wife and three daughters on the ski slopes or at the beach.

Fun Fact: Joe Jr. has jumped out of a perfectly operational airplane – twice – and lived to tell about it.

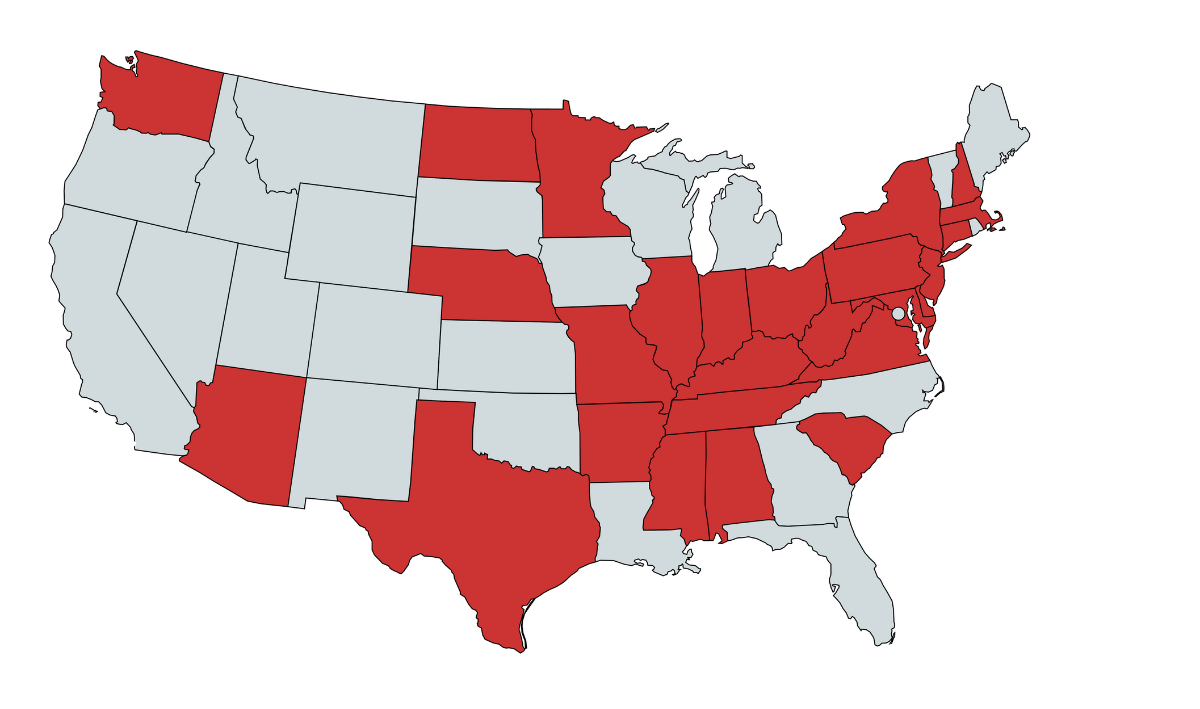

Career Highlight(s): Gaining a national reputation with fast track projects for Amazon, North American Coal, US Silica, Hudson Yards, Exelon and Kimberly Clark.

Notable: Named to Central Penn Business Journal’s 40 under 40 in 2013. Invited to membership in Young Presidents Organization in 2017, member Philadelphia Union League, member American Welding Society, member AISC.