Some say we are an outlier. We play a different game than the competition by never backing down to a rapid, high-stakes challenge. From turnkey construction, to steel fabrication and erection, to process piping and mechanical installs, we have completed some of the nation’s most unique and complex projects.

When it comes to process piping and mechanical installation, following the details and quality standards through every part of fabrication is critical. But that’s never stopped us from taking on a challenging project. To learn more about process piping and mechanical installs, JGM’s capabilities in this service area, and our most noteworthy process piping projects, keep reading.

What is Process Piping & Mechanical Installation?

Process piping is used in industrial facilities to transport liquids and gases from one location to another. Complex piping systems and valves are often found in breweries, pharmaceutical plants, chemical processing facilities, and many other industrial spaces where materials need to be mixed and separated to manufacture goods.

Unlike plumbing piping, which uses copper or plastic pipes to move water, process piping is much more complex. Not only do process piping systems move liquids and gases (which are sometimes hazardous) they also must be designed to follow Occupational Health and Safety Standards. For example, if a process piping system will be used to move hot liquids, the pipes must be designed and manufactured using a heat resistant material. Depending on the specific industry and the intended use of the pipes, each system must be designed and built very differently to ensure they can operate safety and efficiently.

Once the process piping systems are designed and fabricated to high quality and safety standards for their specific use, they need to be installed in the industrial facility where they will operate. This requires an understanding of mechanical functions and how the system will operate.

What Are JGM’s Process Piping & Mechanical Install Capabilities?

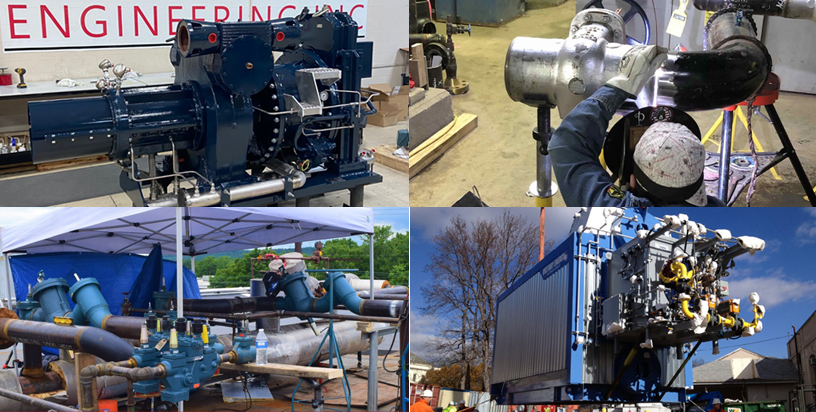

Our team has worked with contractors in several industries to address their most complex process piping and mechanical install needs. From planning and design to fabrication and installation, our team has the experience and skillsets to bring any process piping system to life.

Some of our most common process piping systems we fabricate and install include:

- Utility Piping Systems

- Alloy Piping Systems

- Victaulic Piping Systems

- ANSI/ASME B31.3: Chemical Plant and Petroleum Piping

- ANSI/ASME B31.1: Power Piping

- ANSI/ASME B31.5: Refrigeration

- And Much More!

At JGM, we understand it is critical the process piping system is an exact fit to the facility where it is being installed. Using 3-D scanning and 3-D modeling technology, we guarantee a 100 percent fit up. Plus, our state-of-the-art facility in Coatesville, Pennsylvania allows us to prefabricate up to 90 percent of the piping prior to installation. Once the piping system has been installed, our team has a variety of testing procedures to ensure the project will be able to pass inspections and obtain the required permits to operate in the manufacturing facility.

What Are JGM’s Notable Process Piping & Mechanical Install Projects?

Because it is not in our blood to say “no,” we have completed countless process piping and mechanical install projects over the past 20 years. Some of our most recent, notable projects include:

- Gas Turbine Starting System Stainless Steel Piping – Partnering with Koenig Engineers, our team fabricated a complex, custom stainless steel piping system to be used in the power industry.

- Fast Track Spiral Flash Freezer Project – Contracted by SSOE Group, JGM fabricated a piping system for a food client which allowed them to freeze their finished goods much faster and using less energy.

- Boiler Feedwater Pump Replacement – Covanta Energy trusted JGM with removing and upgrading three boiler feedwater pumps at their Harrisburg, PA location. Our team was responsible for replacing all associated piping, valves, insulation, hangars, and structural supports.

We’re Up for the Challenge

Need support with a process piping or mechanical install project? We’re up for the challenge! At JGM, we pride ourselves on completing projects effectively and quickly all while uncompromising safety. With over 20 years’ experience and a project portfolio that speaks for itself, trust us with your next process piping and mechanical install project!